Careers

Become part of a dynamic, fast-growing company that appreciates talent and invests in your development.

Thank you for your interest in joining our team at The Ritual Works.

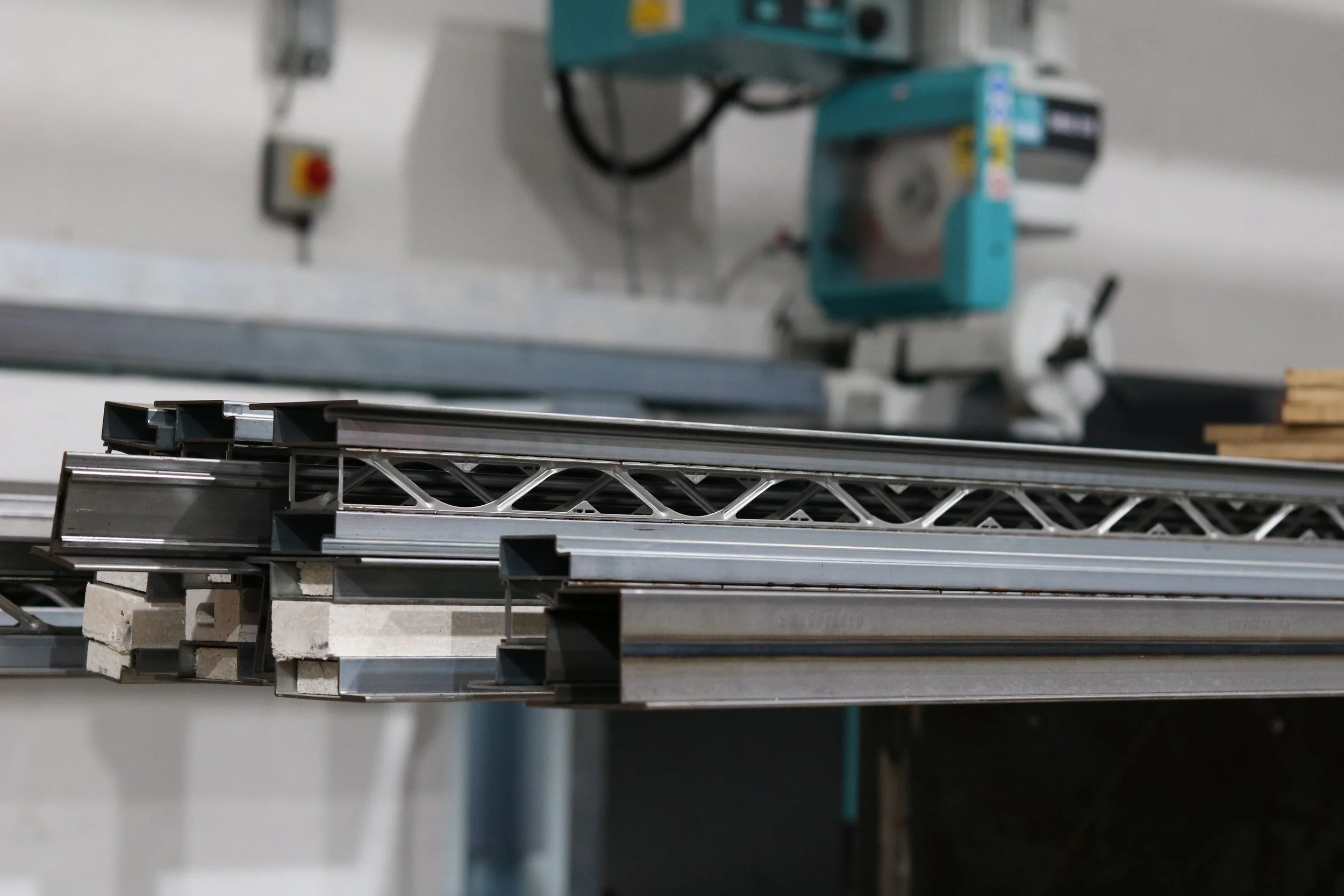

Steel Profile Systems Fabricator

About The Ritual Works

The Ritual Works is a fabrication company that specialises in providing manufacturing solutions to various industries, from roofing and cladding and electrical engineering to architecture, the automotive industry, catering and medical. We take the best of traditional techniques and streamline them using state-of-the-art machinery and equipment. We fully embrace innovation and investment back into our factory and our staff. The Ritual Works is a place for people to learn, strive and excel in their talents.

Job Description

We’re looking for an experienced fabricator to build fire-rated steel doors, screens, and partitions from a modular, slimline, Swiss-engineered profile system. You’ll work from system manuals and cutting lists to produce EI/EW-rated assemblies (typically EI30–EI120) with narrow sightlines, using system-specific tooling, jigs, crimping/press techniques, and advanced TIG/MIG welding for approved joints and reinforcements. Precision, documentation, and compliance are central to this role.

Key Responsibilities

Drawings & System Manuals: Read technical drawings, approvals, and fabrication manuals; generate/verify cutting lists and machining data.

Profile Preparation: Mitre, notch, and machine hollow steel profiles; preserve thermal breaks where applicable; install corner connectors/cleats and mechanical fasteners.

System Assembly: Use crimping/press tools, staking/pinning, and execute approved welds to achieve square, true frames with controlled leaf-to-frame gaps.

Advanced Welding:

> Fabricate and weld hinge/backing plates, lock-case reinforcements, thresholds, transom/mullion stiffeners, and sub-frames.

> Control heat input, distortion, and HAZ to protect sightlines, coatings, and fire performance; dress/grind welds for powder-coat/galvanised finishes.

> Perform advanced TIG/MIG on thin-wall profiles and reinforcements (fillet, plug, stitch, and continuous runs where permitted by approvals/WPS).

Hardware Integration: Prep and fit hinges, multipoint locks, panic/escape devices, thresholds, concealed/overhead closers, and strike plates using system punching dies and templates.

Fire-Rated Glazing: Dry-glaze approved fire-resistant glass with setting blocks, pressure plates/beads, intumescent liners, and approved sealants/adhesives.

Quality & Compliance: Work to EN 1634-1/-3, EN 16034 and UKCA/CE requirements; complete traceability records, in-process inspections, and final QC (squareness, diagonals, gap checks).

Finishing & Protection: Prepare for finishing (e.g., galvanised/powder-coated substrates), protect edges and thermal insulators, and package assemblies for transport.

Equipment Care: Operate and maintain double-mitre saws, copy routers, punching stations, crimping presses, mills, and welders; perform routine maintenance and minor repairs.

Collaboration & Safety: Liaise with engineers/designers on tolerances and buildability; follow factory SOPs, PPE, COSHH, and safe lifting practices.

Requirements

Proven experience fabricating fire-rated, slimline steel door/screen systems (mechanically jointed mitred frames with corner cleats/crimping, narrow sightlines).

Advanced welding proficiency (required):

> Expert TIG/MIG on thin-gauge mild/stainless steel profiles (≈1.5–3.0 mm), multi-position.

> Ability to interpret and work to WPS/PQR, manage parameters (heat input, interpass), and deliver cosmetically clean, structurally sound, approval-compliant welds.

> Coded welder qualification to BS EN ISO 9606-1 (or equivalent).

Strong metalworking skills: precision cutting, machining, crimping/pressing, and assembly to tight tolerances.

Confident in reading technical drawings/system manuals and producing accurate cutting/machining lists.

Hands-on with system-specific tooling: punching dies for hardware/drainage, copy-routing/slotting, corner crimping/staking presses.

Knowledge of fire and smoke control assemblies (EI/EW ratings, clearances, intumescent components, permitted sealants/adhesives).

Experience dry-glazing fire-rated glass within approved compositions.

High attention to detail, documentation discipline (traceability, QC checklists).

Physical stamina for handling steel profiles and glazed units safely.

Problem-solving mindset and clear communication; strong commitment to safety and quality.

Advantageous Skills

Familiarity with thermally broken steel series and external door elements.

Awareness of NDT/visual weld inspection basics and ISO 5817 quality levels.

Experience with UKCA/CE labelling and factory production control (FPC) records.

Employment Type & Compensation

Full-Time: Salary negotiable & experience-dependent.

This position is required for 38 hours a week

4-day weeks (Mon-Thu/8am-18pm)